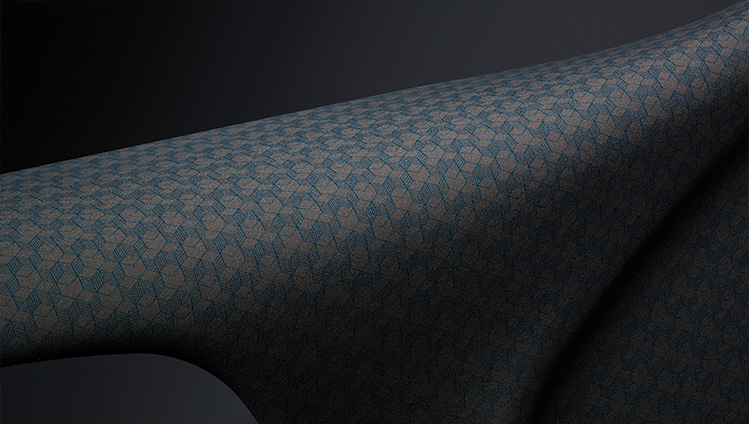

With the thermoplastic malleable surface material Xpreshn®, the name says it all. Expressive is the motto, because the decorative material is available not only in a wide variety of colors, but also in a whole range of grain designs. Based on polyolefins, the material is characterized above all by its low weight and excellent aging resistance. The extremely durable surface is available in two versions - compact foil and foam laminate.

Xpreshn® – 100 per cent quality, up to zero per cent carbon emissions

Within the Xpreshn® product line, Continental offers the first completely CO2-neutral interior surface. It consists of a combination of polyolefin recyclates and bio-based raw materials originating from plant waste. The recyclates used can come from film production waste („post-industrial“), but also from households and vehicles („post-consumer“).

Due to these parameters, latest Xpreshn® variants have a significantly better CO2 balance compared to the standard film. In addition, the film is flexible in processing and free of any halogens and plasticizers. An absolute sustainability bonus on top? The films are thermoplastic monomaterials and can be fully recycled using industrialized processes.

Xpreshn® considerably reduces carbon footprint

The high-quality surface material Xpreshn® can be produced in a variety of customized solutions. Based on the respective design, different PCF values result for the respective variants, which provide information on how climate-friendly a product is.

Xpreshn® as drop-in solution

Another plus of the sustainable Xpreshn® variants? Without compromising on quality and performance, the climate-friendly designs can easily be integrated into existing production processes. No special adjustments are required to use the sustainable Xpreshn® variants.

Product Benefits

- CO2-neutral interior surface possible

- Contribution to circular economy

- Combination of bio-based and recycled raw materials

- Bio-based polyolefins are produced from waste-based plant materials in an effective and streamline process with low CO2 pollution)

- Designed for recycling

- Thermomechanical recycling industrialized for volume production

- State-of-the-art chemical recycling for volume production

- All known advantages of Xpreshn® and Xpreshn HD® products

Material Design

- Design: compact foil and foam laminate

- Thickness: 0.8 mm – 1.4 mm and 2.0 mm – 3.5mm

- Application: Instrument panel, doors/sides/center console, seat backs

- Material backing: Polyolefin foam

- Processing: Vacuum thermoforming, vacuum laminating, back foam backing, low pressure molding, in-mold graining, thermal welding

Material Cross Section

Compact Foil

1 | Lacquer Finish

2 | Compact Layer

4 | Compact Layer

5 | Backside Primer (optional)

Foam Laminate

1 | Lacquer Finish

2 | Compact Layer

3 | Foam Layer

5 | Backside Primer (optional)

One material, numerous designs

The Xpreshn® surface material is also available in the following variants:

Xpreshn HD® and Xpreshn HD® Light (weight reduction and excellent grain stability)

Other properties can be developed as needed:

- Xpreshn®/Xpreshn® HD Protect (high scratch resistance and excellent grain stability)

- Xpreshn® optional LFT design (Optimization Low Force Tearing (LFT) applications)

- DecoJect® (low-cost alternative to painted injection-molded parts)

- DecoJect Hylite® (translucent material)